-

25

2025-11

What are the hazards of poor cell consistency in power batteries?

We know that a car's battery is composed of many battery cells. Generally, modules are composed of battery cells, and the modules form a PACK. For example, the Tesla Model S's battery system is carefully composed of 7104 18650 lithium batteries. The Xiaomi SU7 Max battery pack is composed of 198 battery cells connected in series. With so many battery cells, if one of them is faulty, it's easy to carry the whole into the ditch. As a familiar saying goes, "A piece of mouse dung will kill a pot of porridge". So the consistency of battery cells in power batteries is very important. 1、 The harm caused by poor consistencyPoor consistency of battery cells in power batteries can cause various hazards, directly affecting battery performance, safety, lifespan, and overall vehicle reliability. The following is a specific analysis of hazards and mechanisms:① Capacity degradation and battery life decreaseShortboard effect: In cells with poor consistency, the unit with the lowest capacity will be the first to fully charge or empty, resulting in the overall available capacity of the battery pack being limited by the "weakest cell".Example: If the capacity of a certain battery cell is 10% lower than others, the entire battery pack capacity may be lost by 5% to 8%, significantly reducing the vehicle's range. ② Safety hazards: thermal runaway, fire and explosionRisk of overcharging/overdischarging: When the voltage is inconsistent, some cells may be forcibly charged to overvoltage (>4.3V) or discharged to undervoltage (<2.5V), causing lithium dendrite growth, piercing the diaphragm and causing internal short circuit, ultimately leading to thermal runaway.Uneven heat distribution: Cells with large internal resistance or temperature differences overheat locally during charging and discharging, forming "hotspots" and accelerating heat diffusion. ③ Significantly shortened battery lifeAging acceleration: Cells with poor consistency are subjected to uneven loads during cycling. For example, repeated overdischarging of low capacity cells can accelerate the decay of electrode materials, potentially shortening their lifespan by 30% to 50%.Chain reaction: The failure of a single battery cell (such as a sudden drop in capacity) will force other battery cells to compensate, exacerbating overall aging. ④ Failure of Battery Management System (BMS)SOC/SOH estimation distortion: BMS relies on cell parameter consistency for precise management. If the difference in battery cells is too large, BMS may not be able to accurately estimate the remaining state of charge (SOC) or state of health (SOH), and may misjudge the battery status.Overload of balancing function: BMS needs to frequently balance cells with significant differences, resulting in increased energy consumption and limited effectiveness, ultimately leading to overload or failure of the balancing circuit.2、 How to screen out cells with poor consistencyThe following are the methods and steps for consistency screening of battery cells:① Voltage matching: That is, OCV testing measures the open circuit voltage (OCV) of the battery cell after it has been idle (usually 24-48 hours), and eliminates cells with voltage deviations exceeding the set threshold (such as ± 5mV).② Capacity sorting: Obtain the actual capacity of the battery cells through charge and discharge tests, and divide them into capacity intervals (such as ± 1%) to ensure that the difference in battery cell capacity within the same battery pack is minimized. ③ Internal resistance screening: Measure the DC internal resistance (DCR) or AC internal resistance (ACR), and remove cells with high internal resistance or large dispersion (such as internal resistance deviation>3%). ④ Self discharge rate (K value) test: After fully charging the battery cell, let it stand for 7-14 days, calculate the self discharge rate (K value) based on the voltage drop, and screen for cells with similar K values (such as K value difference<0.5%). The role of K=(OCV1- OCV2)/(t2- t1) K value testing should not be underestimated.⑤ Aging and cycle testingHigh temperature aging screening: Place the battery cells in a high-temperature environment (such as 45 ℃) and monitor the voltage decay rate to screen for cells with consistent aging characteristics. Cycle life pre-test: Perform a small amount of charge and discharge cycles on the battery cell (such as 50 times) to eliminate cells with abnormal capacity decay or sudden internal resistance changes.When selecting power batteries, the quality of the battery cells will greatly affect the performance of the entire battery pack, so it is necessary to conduct strict inspections of product quality and suppliers in the early stage. As a professional lithium battery supplier,Be Power is committed to providing customers with high-quality and customized solutions;We are the number one Chinese battery supplier delivered to automotive OEM in Brazil.We offered battery for over 800K set HESS systems;We are the best UTV battery supplier and exporter in China, with over 15 years of experience in lithium battery research and development.We are the best battery pack solutions provider in China.Our battery systems are warmly welcomed in over 30 countries applied on electric trucks,electric light vehicles,electric UTV, electric sweepers, container energy storage systems, 215Kwh commercial and industrial energy storage systems etc. With top-notch technical team in China we are providing the toughest technical and highest level safety products.

-

24

2025-10

Congratulations to our partner Great Power for being listed as a BNEF Tier1 global first tier energy storage manufacturer for 4 consecutive times!

Great Power has been listed as a BNEF Tier1 global first tier energy storage manufacturer for four consecutive times! Recently, Bloomberg NEF (Bloomberg New Energy Finance, abbreviated as BNEF), a globally renowned research institution, officially released the Global Tier 1 Energy Storage Tier 1 List 2Q 2025 for the second quarter of 2025.BNEF rigorously evaluates project scale, technological innovation, supply chain resilience, financial health, and global market influence from multiple dimensions. Every year, only the top energy storage companies with comprehensive strength are selected to enter the Tier 1 list. Its rating results are regarded as industry benchmarks by global energy giants, investment institutions, and governments.Great Power has made a strong breakthrough among global energy storage companies with its innovative product technology, leading intelligent manufacturing, efficient global delivery system, and full cycle project execution control capabilities. It has been ranked as a BNEF Tier 1 global first level energy storage manufacturer for four consecutive times, marking Great Power's continuous recognition of its comprehensive strength by international authorities!As the overseas partner of Great Power, Be Power is committed to providing customers with high-quality and customized solutions;We are the number one Chinese battery supplier delivered to automotive OEM in Brazil.We offered battery for over 800K set HESS systems;We are the best UTV battery supplier and exporter in China, with over 15 years of experience in lithium battery research and development. Our battery systems are warmly welcomed in over 30 countries applied on electric trucks,electric light vehicles,electric UTV, electric sweepers, container energy storage systems, 215Kwh commercial and industrial energy storage systems etc. With top-notch technical team in China we are providing the toughest technical and highest level safety products!

-

05

2025-09

Lithium battery voltage consistency: importance, impact, and how to improve it

The importance of voltage consistency in lithium batteries.The voltage consistency of lithium batteries refers to the ability of individual lithium batteries in the same batch or system to maintain consistent terminal voltage under the same operating conditions. Voltage consistency has a crucial impact on the performance, lifespan, and safety of lithium battery packs. 1. Voltage consistency is related to the overall performance of lithium battery packs.In a battery pack, if there is a voltage difference between individual cells, some cells may reach their upper or lower voltage limit in advance during the charging and discharging process, resulting in the entire battery pack not being able to fully utilize its capacity, thereby reducing overall energy efficiency.2. Voltage consistency has a direct impact on the safety of lithium batteries.When the voltage of individual cells in the battery pack is inconsistent, some cells may experience thermal runaway due to overcharging or overdischarging, leading to safety accidents such as fires or explosions. 3. Voltage consistency also affects the lifespan of lithium batteries. Due to inconsistent voltage, some individual cells in the battery pack may experience more charge and discharge cycles, leading to a shortened lifespan and ultimately affecting the overall service life of the battery pack.The impact of inconsistent voltage on lithium batteries1. Performance degradation: The voltage difference between individual cells can lead to a decrease in the overall performance of the battery pack. During the discharge process, batteries with lower voltage will limit the discharge voltage and capacity of the entire battery pack, thereby reducing the energy output of the battery pack. 2. Unbalanced charging and discharging: Inconsistent voltage can cause uneven charging and discharging of the battery pack. Some batteries may be fully charged or emptied in advance, while others may not have reached their charging and discharging limits, which can lead to a decrease in the overall capacity utilization of the battery pack. 3. Risk of thermal runaway: Inconsistent voltage may increase the risk of thermal runaway in the battery pack. Overcharged or overdischarged batteries may generate a large amount of heat. If the heat is not dissipated in a timely manner, it may cause thermal runaway of the battery and result in safety accidents. 4. Shortened lifespan: Inconsistent voltage can lead to increased differences in the lifespan of individual cells within the battery pack. Some batteries may fail prematurely due to excessive charging and discharging, thereby affecting the lifespan of the entire battery pack.How to improve the voltage consistency of lithium batteries1. Strengthen battery management system: Battery management system (BMS) is the key to ensuring battery voltage consistency. By monitoring and adjusting the voltage between battery cells in real-time, BMS can ensure that the battery pack maintains voltage consistency during charging and discharging processes. In addition, BMS can also achieve balanced management of battery packs, avoiding overcharging or overdischarging of individual batteries. 2. Implement regular maintenance and calibration: Regular maintenance and calibration of lithium battery packs can maintain voltage consistency between battery cells. For example, regular charging and discharging calibration of battery packs can ensure that each battery cell reaches the same charging and discharging state, thereby improving voltage consistency. 3. Adopting advanced battery balancing technology: Battery balancing technology is an effective means of improving battery voltage consistency. By actively or passively balancing, the voltage difference between battery cells can be reduced to an acceptable range, ensuring that the battery pack maintains voltage consistency during charging and discharging processes. 4. Improve the usage environment: The usage environment also has a certain impact on the voltage consistency of lithium batteries. By improving the usage environment of batteries, such as reducing temperature fluctuations, minimizing vibration and shock, the impact of environmental factors on battery performance can be reduced, thereby maintaining battery voltage consistency.ConclusionThe voltage consistency of lithium batteries has a significant impact on the performance, safety, and lifespan of battery packs. Inconsistent voltage may lead to performance degradation, uneven charging and discharging, increased risk of thermal runaway, and shortened lifespan of the battery pack. Therefore, improving the voltage consistency of lithium batteries is crucial. Choosing products from high-quality and reliable battery manufacturers can effectively ensure the voltage consistency of lithium batteries, thereby ensuring the safe, stable, and efficient operation of battery packs.Be Power is committed to providing customers with high-quality and customized solutions;We are the number one Chinese battery supplier delivered to automotive OEM in Brazil.We offered battery for over 800K set HESS systems;We are the best UTV battery supplier and exporter in China, with over 15 years of experience in lithium battery research and development.We are the best battery pack solution provider in China.Our battery systems are warmly welcomed in over 30 countries applied on electric trucks,electric light vehicles,electric UTV, electric sweepers, container energy storage systems, 215Kwh commercial and industrial energy storage systems etc. With top-notch technical team in China we are providing the toughest technical and highest level safety products.

-

22

2025-08

What is RCH testing and testing methods for lithium batteries

The RCH testing of lithium batteries is an important means of evaluating their performance and safety. Through these tests, we can understand the performance and safety of batteries under different conditions, and provide important reference for the development and improvement of batteries. Lithium battery RCH test1. R test: Test the charging and discharging performance of the battery, evaluate its performance under different charging and discharging states through cyclic charging and discharging processes, such as capacity, charging and discharging efficiency, energy density, and other parameters.2. C test: Test the cycle life of the battery, evaluate the battery's lifespan and capacity loss by simulating the charging and discharging cycles of the battery in actual use. By conducting the C test, we can understand the degree of performance degradation of the battery under different charging and discharging conditions. 3. H testing: Testing the safety of batteries by examining their performance under extreme conditions such as high temperature, overcharging, and overdischarging to evaluate their safety performance. H testing can identify potential safety hazards in batteries and ensure their safety during use.Test purposeThe purpose of RCH testing for lithium batteries is to evaluate their performance under R (reverse), C (charging), and H (high temperature) conditions, in order to ensure their safety and reliability in practical use.Testing equipment and methods1. Equipment: Lithium battery testing cabinet, constant temperature box, charge and discharge tester, data acquisition system, etc. 2. Method: According to the testing standards, place the lithium battery in a constant temperature chamber to simulate a high-temperature environment. Then, the lithium battery is subjected to reverse charging and discharging operations using a charging and discharging tester, and data is recorded in real-time.Problem examples and improvement measures1. Problem: During the charging process, some lithium batteries experience a rapid temperature rise.Improvement measures: Optimize charging strategy, reduce charging current to slow down temperature rise rate.2. Problem: The capacity of some lithium batteries has decreased.Improvement measures: Optimize the manufacturing process of lithium batteries to improve their capacity retention rate in high-temperature environments.ConclusionThrough RCH testing, we can discover the performance of lithium batteries in high-temperature environments, which can be optimized to address existing issues and provide strong guarantees for their safety and reliability in practical applications.

-

14

2025-07

The difference between AC impedance and DC internal resistance of lithium batteries

In the research and application of lithium batteries, internal resistance is an important parameter that reflects the energy loss and electrochemical reaction state inside the battery. Internal resistance is mainly divided into DC resistance and AC impedance. This article will provide a detailed introduction to the difference between AC impedance and DC internal resistance of lithium batteries.1.Definition and measurement methods① DC internal resistance (DCR): DC internal resistance refers to the ratio of the voltage change of a battery to the corresponding discharge current change under working conditions. It is usually expressed in ohms (Ω) and can be measured using a dedicated battery internal resistance tester or multimeter with current and voltage settings. ② AC Impedance: AC impedance is derived by injecting sine wave current signals into the positive and negative terminals of a battery, and detecting the sine wave voltage signals at the other two terminals.2. Characteristics① Characteristics of DC internal resistance measurement: Suitable for large capacity batteries: This method requires applying a large test current (40-80A, 2-3 seconds), which small capacity batteries may not be able to withstand. Short testing time: High current can cause polarization resistance, so the testing time must be short to avoid excessive impact on the battery. There may be losses: High current testing may cause certain losses to the battery.② Characteristics of AC internal resistance measurement: Short testing time: AC internal resistance measurement only requires the application of a fixed frequency and current (currently 1KHz, 50mA), sampling voltage, rectification and filtering processing, and calculation of resistance value through an arithmetic circuit. The entire process only takes 0.1 seconds. Suitable for various battery types: Due to the small testing current, it causes almost no damage to the battery, making it suitable for almost all battery types. Relatively low accuracy: The accuracy of the AC internal resistance testing method is 1% -2%, which is not as accurate as the DC internal resistance testing method.3. Reflected information① DC internal resistance: DC internal resistance more directly reflects the Ohmic impedance inside the battery, including the resistance of electrode materials, electrolyte, separators, and other parts. It can provide information about the internal conductivity of the battery.② AC impedance: In addition to Ohmic impedance, AC impedance can also reflect the electrochemical reaction impedance inside the battery. The semi-circular part is related to the charge transfer at the interface between the electrolyte and electrode material, while the low-frequency part is related to the diffusion of lithium ions in the electrolyte and positive and negative electrode materials. AC impedance can provide more comprehensive information on battery electrochemical reactions4. Application scenarios① DC internal resistance: DC internal resistance is commonly used to evaluate the power performance and performance of batteries in practical use. It is of great significance for the discharge capacity and charging efficiency of batteries. ② AC impedance: AC impedance is widely used in battery research and development, quality control, and electrochemical analysis. It can help study the electrochemical reaction mechanism, interface performance, and aging process of batteries.5. The influence of temperature, state of charge, and charge discharge state① Temperature: Temperature has a significant impact on the internal resistance of lithium batteries. Generally speaking, as the temperature decreases, the internal resistance of the battery will increase. This is because ion transport and electrochemical reaction rates slow down at low temperatures.② State of Charge (SOC): The state of charge of a battery also affects its internal resistance. During the discharge process, as the discharge depth increases, the internal resistance usually increases. This is due to changes in the internal electrochemical reactions of the battery and changes in the electrode structure.③ Charging and discharging status: Charging and discharging status can also affect internal resistance. For example, during the charging process, the internal resistance of the battery may increase, while during the discharging process, the internal resistance may decrease.6. Overall considerationIn practical applications, the measurement results of DC internal resistance and AC impedance are usually considered comprehensively to gain a more comprehensive understanding of battery performance. DC internal resistance can more accurately reflect the superposition of various resistances and capacitances inside the battery, while AC impedance provides more information about electrochemical reactions. Meanwhile, by analyzing factors such as temperature and state of charge, the health status and performance of the battery can be more accurately evaluated.7. SummaryThere are significant differences in the definition, measurement methods, characteristics, and reflected information between the AC impedance and DC internal resistance of lithium batteries. Understanding these differences helps us choose appropriate testing methods and interpret test results correctly, thereby better evaluating the performance and status of lithium batteries. In practical applications, according to specific needs and conditions, one can choose to use DC internal resistance testing or AC impedance testing, or combine the two for a more comprehensive analysis.

-

25

2025-06

Detailed explanation of the basic knowledge of lithium battery voltage: open circuit voltage

The voltage characteristics of lithium batteries are the core indicators for measuring their performance and safety, directly affecting the charging and discharging efficiency, cycle life, and application safety of the battery. This article will systematically introduce four key voltage parameters of lithium batteries - open circuit voltage (OCV), operating voltage (WV), discharge cut-off voltage (DCV), and charge limiting voltage (LCV), to help you comprehensively understand the definition, influencing factors, and practical application points of voltage parameters.This article provides a detailed explanation of the open circuit voltage involved.1. Open circuit voltage (OCV)Open circuit voltage (OCV) refers to the voltage value of a circuit when the power supply or component is disconnected from the load. It reflects the electromotive force of the power supply or the inherent voltage characteristics of the components when no current passes through, for example, the open circuit voltage of a battery is usually close to its nominal voltage, while the open circuit voltage of a capacitor is consistent with its charged voltage.The open circuit voltage is the potential difference between the positive and negative electrodes of a lithium battery in its non working state (with no current flowing), determined by the chemical equilibrium potential difference of the positive and negative electrode materials. OCV is an important basis for evaluating the state of charge (SOC) of a battery, and its value shows a regular curve as the remaining capacity of the battery changes.The OCV of lithium batteries with different material systems shows significant differences:Ternary lithium battery: OCV is about 4.2V when fully charged, and drops to 3.6-3.7V when discharged to 50% SOC;Lithium iron phosphate battery: The OCV at full charge is about 3.65V, and the platform voltage remains stable at around 3.2V; Lithium manganese oxide battery: The OCV range is similar to that of ternary batteries, but the voltage platform is slightly lower. In practical applications, OCV needs to be measured after the battery has been idle for more than 2 hours to avoid numerical deviation caused by polarization effects after charging and discharging. Long term storage of lithium batteries is recommended to maintain a 70% SOC (corresponding to an OCV of approximately 3.8V) to minimize capacity degradation.2. Measurement method and key points of open circuit voltage (OCV) of lithium batteriesRequirements for measuring tools and equipment① Core ToolsWhen using a DC voltmeter (such as a multimeter or specialized battery tester) to directly connect the positive and negative terminals of the battery for measurement, it is necessary to ensure that the instrument resolution is ≥ 0.1mV, the accuracy meets the error requirements under the 10V range, and has temperature compensation function.② Key parameters for selection:Resolution: High resolution (such as 0.1 μ V level) can identify small voltage differences, facilitating early detection of defective cells; Accuracy: Calculated based on "reading error+resolution error", it is recommended to use a 10V range for a 4V battery; Temperature compensation: Every 1 ° C change in ambient temperature may cause OCV to fluctuate by hundreds of μ V, which needs to be converted to the standard temperature value through compensation function.Measurement steps and timing3. Precautions① Polarization effect differentiationOCV1 (Instantaneous Voltage): The initial value measured immediately after charging and discharging, which is greatly affected by polarization;OCV2 (Stable Voltage): The equilibrium value that eliminates polarization after settling, which is closer to the true electrochemical equilibrium potential and is the core basis for evaluating SOC and SOH.② Environmental controlMaintain stable measurement environment temperature or correct readings through device temperature compensation function to avoid measurement errors caused by temperature fluctuations.③ Safe operationConfirm that the battery has no physical damage before measurement to avoid short circuits; High voltage battery packs require the use of insulated tools to prevent the risk of electric shock.4. Application scenariosProduction screening: Remove defective cells with abnormal self discharge through OCV differences to ensure consistency of the battery pack;Performance evaluation: Analyze battery capacity degradation and aging degree by combining OCV-SOC curve (such as discharge platform voltage);BMS optimization: Real time monitoring of OCV to dynamically adjust charging and discharging strategies, extending battery cycle life.5. Special measurement method (patented technology)Rapid testing method: By short-term charging and discharging (<5s) and multiple cycles of depolarization, the settling time is shortened (the total testing time is reduced by more than 50%), which is suitable for mass production rapid testing scenarios.Curve fitting method: Draw an OCV curve by combining the midpoint of the charge discharge voltage curve to improve the accuracy of SOC estimation. Note: In actual operation, the measurement scheme should be selected according to the application scenario (laboratory/production line). For high-precision scenarios, specialized battery testers should be prioritized and environmental variables should be strictly controlled.6. SummaryIn summary, open circuit voltage (OCV), as the core electrochemical characteristic parameter of lithium batteries in non working states, is not only a key basis for evaluating the state of charge (SOC), but its numerical differences also directly reflect the inherent characteristics of different material systems (such as ternary, lithium iron phosphate, lithium manganese oxide). By standardizing the measurement process (static elimination of polarization, high-precision equipment and temperature compensation) and scientific analysis methods (OCV-SOC curve, rapid measurement technology), OCV plays an irreplaceable role in production screening of defective cells, evaluation of battery aging degree, optimization of BMS charging and discharging strategies, and other scenarios. In practical applications, it is necessary to pay attention to the differentiation of polarization effects and environmental control, while following the maintenance principle of long-term storage to maintain 70% SOC (OCV about 3.8V), in order to maximize the performance stability and cycle life of lithium batteries.

-

06

2025-05

What are the main structural components of lithium-ion batteries?

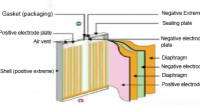

Lithium ion batteries are an important energy storage device widely used in fields such as mobile electronic devices and electric vehicles. This article will provide a detailed introduction to the main structural components of lithium-ion batteries, including positive electrode materials, negative electrode materials, electrolytes, separators, and current collectors. Meanwhile, the influence of different materials on the performance of lithium-ion batteries will also be explored. Through a deep understanding of the structure of lithium-ion batteries, theoretical foundations can be provided for battery design and optimization.1. IntroductionLithium ion battery is a type of battery that converts electrical energy through the migration of lithium ions between the positive and negative electrodes. It has the advantages of high energy density, low self discharge rate, and long cycle life, and is therefore widely used in various electronic devices and transportation vehicles. The performance of lithium-ion batteries mainly depends on their structural composition, so a deep understanding of the structural composition of lithium-ion batteries is of great significance for battery design and optimization.2、 Positive electrode materialThe positive electrode material is an important component of lithium-ion batteries, whose main function is to store and release lithium ions. Common positive electrode materials include lithium manganese oxide, lithium cobalt oxide, ternary materials, etc. Lithium manganese oxide has a high specific capacity and low cost, but a short cycle life; Lithium cobalt oxide has a high specific capacity and good cycle life, but the cost is relatively high; Ternary materials have high specific capacity and good cycle life, but they are expensive. Therefore, in practical applications, it is necessary to select suitable positive electrode materials according to specific needs.3、 Negative electrode materialNegative electrode material is another important component in lithium-ion batteries, whose main function is to store and release lithium ions. Common negative electrode materials include graphite, silicon, etc. Graphite has a high specific capacity and good cycle life, but its capacity is limited; Silicon has a high specific capacity, but the capacity decays rapidly. Therefore, in practical applications, a balance needs to be struck between graphite and silicon to meet the needs of different application scenarios.4、 ElectrolyteThe main function of electrolyte is to provide a transport medium for lithium ions. Common electrolytes include organic electrolytes and solid electrolytes. Organic electrolytes have high conductivity and good lithium ion transport performance, but there are safety hazards such as combustion and volatilization; Solid electrolyte has good safety performance, but low conductivity. Therefore, in practical applications, it is necessary to choose the appropriate electrolyte based on safety and performance requirements.5、 DiaphragmThe main function of the diaphragm is to prevent short circuits between the positive and negative electrodes. Common membranes include polyolefin membranes, ceramic membranes, etc. Polyolefin film has good electrical conductivity and isolation performance, but poor thermal stability; Ceramic membranes have good thermal stability and isolation performance, but low electrical conductivity. Therefore, in practical applications, it is necessary to choose a suitable separator based on the safety and performance requirements of the battery6、 Collector fluidThe main function of a current collector is to collect and distribute electrical current. Common current collectors include copper foil, aluminum foil, etc. Copper foil has good conductivity and mechanical strength, but it is relatively expensive; Aluminum foil has a lower price, but its conductivity is poor. Therefore, in practical applications, it is necessary to choose a suitable current collector based on cost and performance requirements.7. ConclusionThe main structural components of lithium-ion batteries include positive electrode material, negative electrode material, electrolyte, separator and current collector, sealing ring, positive electrode cap, battery case, etc. The selection of different materials has a significant impact on the performance of lithium-ion batteries. By delving into the structural composition of lithium-ion batteries, a theoretical foundation can be provided for battery design and optimization. In the future, with the advancement of technology, the structural composition of lithium-ion batteries may change to meet higher performance and safer requirements.

-

16

2025-04

The difference between power batteries and energy storage batteries

Both are lithium batteries, why are they divided into energy storage batteries and power batteries? I think many people have this question? Here we will introduce the differences between them. Although energy storage batteries and power batteries are typically based on lithium-ion technology (such as lithium iron phosphate or ternary lithium), they have significant differences in design, performance, and lifespan due to their vastly different application scenarios and requirements. Simply put, it can be understood using a metaphor:Power battery - like sprinters: pursuing explosive power, speed, and agility (high power, high energy density). For example, many electric vehicle batteries nowadays can be charged quickly, with slow charging taking 8 hours and fast charging taking only 30 minutes to fully charge. Energy storage batteries - like marathon runners: pursuing endurance, stability, and cost-effectiveness (long lifespan, high safety, low cost). Below, we will make a detailed comparison from several dimensions. Please refer to the table below:Although there are many differences between power batteries and energy storage batteries, the core principle of the battery cell is the same, consisting of a positive electrode, a negative electrode, a separator, and an electrolyte. But there will be significant differences in design and material selection. For example, if a power battery requires high rate charging and discharging, it needs to choose a positive electrode material with better conductivity, and the D50 of the material should be as small as possible. At the same time, conductive agents such as CNT should be added to the formula to improve performance. In addition, in order to pursue high magnification, the compaction density and surface density cannot be made too high. Our current energy storage cells are mostly based on 280Ah and 314AH, and are mostly stacked. And power batteries come in both wound (cylindrical and square) and laminated (square) forms.Due to the characteristics of different projects and lithium batteries, battery manufacturers need to make corresponding adjustments based on customer needs.Be Power specializes in providing lithium-ion batteries for various applications and customized solutions for customers. Welcome to our official website for more information: www.bepower.com.cn

-

16

2026-01

How important is cell consistency for battery modules!

Due to the differences in voltage, capacity, charge capacity, internal resistance, discharge plateau, and constant current ratio among the individual cells, the charging and discharging rates of the battery module composed of individual cells cannot be synchronized and consistent during charging and discharging, which will shorten the service life of the entire battery module.Therefore, separate capacity treatment must be carried out to make the single battery of the same module have the same voltage; Consistent cycle life; Consistent capacity; Consistent self discharge; Consistent electrical charge; Consistent internal resistance; Consistent discharge platform; Consistent constant current ratio.Consistent voltage:① Inconsistent voltage in series circuits can cause overcharging and overdischarging, and the manager cannot control the battery system; ② The parallel circuit voltage is not consistent, and the batteries are charged and discharged evenly between each other until the voltage is consistent. But if the pressure difference between them is too large, the fuse (PCB board structure) will be blown, and the fuse is allowed to have a pressure difference of less than 0.6V;③ If there is a large pressure difference between the series modules, it can only be resolved through active balancing by BMS. In severe cases, manual charging and discharging or removal of faulty batteries by after-sales service is required.2. Consistent capacity:Inconsistent capacity is the main cause of voltage inconsistency, and there is a risk of overcharging and overdischarging during the charging and discharging process.3. Consistent electrical charge:Even if the battery capacity is the same, if the charged amount is not the same, it can still cause overcharging and overdischarging phenomena.4. Consistent internal resistance:Each individual physical battery can theoretically be divided into two parts: a pure battery and an internal resistance, and inconsistent internal resistance will cause asynchronous charging and discharging of the pure battery.

-

13

2025-02

587Ah large battery cell, building the value foundation of TWh era with reliability, efficiency and stability

587Ah high-capacity energy storage battery cells are committed to leading energy storage from the era of engineering integration to a new era of native reliability with reliability and efficiency. Building the cornerstone of trust with reliability. On the safety level, the three major safety technology cornerstones firmly establish the intrinsic safety defense line of Fengpeng Big Battery 587Ah. The product has passed multiple rigorous safety tests such as thermal runaway, overcharging, and short circuit. Efficiently enhancing value density, we continuously drive efficiency leaps through ten thousand cycle technology and ion sponge technology platform technology. Currently, we have achieved high energy efficiency performance across all temperature ranges, with energy efficiency reaching 85% at 5 ℃, exceeding 95% at 25 ℃, and exceeding 96% at 45 ℃; At room temperature, the 0.5P cycle life has exceeded 10000 times, significantly increasing customer value.The application of energy storage is expanding from a single photovoltaic system to various extremely complex environments such as power grid peak and frequency regulation, industry and commerce, islands, and high-altitude extreme cold. The traditional 'one size fits all' battery cell solution is difficult to meet the high-performance and reliability requirements of energy storage systems in differentiated scenarios.Based on the LTSC low-temperature superconducting communication platform and high-temperature long cycle platform technology, we have developed and laid out the full temperature range multi scenario Fengpeng high-capacity battery cell 587Ah, fully expanding the application boundaries of energy storage, and committed to helping energy storage projects operate safely, efficiently, and stably in diverse global scenarios. Large capacity battery cells are a key technological carrier for the energy storage industry to shift from cost competition to value trust. We will always adhere to technology as the foundation, continuously empower the industry with "reliable and efficient" energy storage product solutions, and strive to work together with customers to build a trustworthy, reliable, and efficient energy storage TWh era new ecology.